Gas lift slowly becoming more efficient

By John Murphy, Houston

For decades the oil industry has used gas lift technology to coax oil from under-pressured reservoirs. Most often these reservoirs have lost the ability to flow on their own because the original gas that acted as the pressure driving the oil has been produced over time. Often this gas depletion occurs over a very short period of time stranding most of the original oil in place.

For decades the oil industry has used gas lift technology to coax oil from under-pressured reservoirs. Most often these reservoirs have lost the ability to flow on their own because the original gas that acted as the pressure driving the oil has been produced over time. Often this gas depletion occurs over a very short period of time stranding most of the original oil in place.

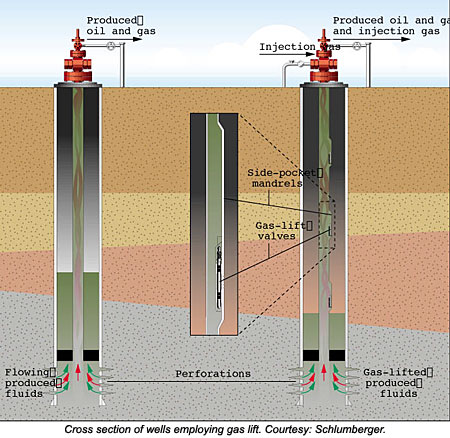

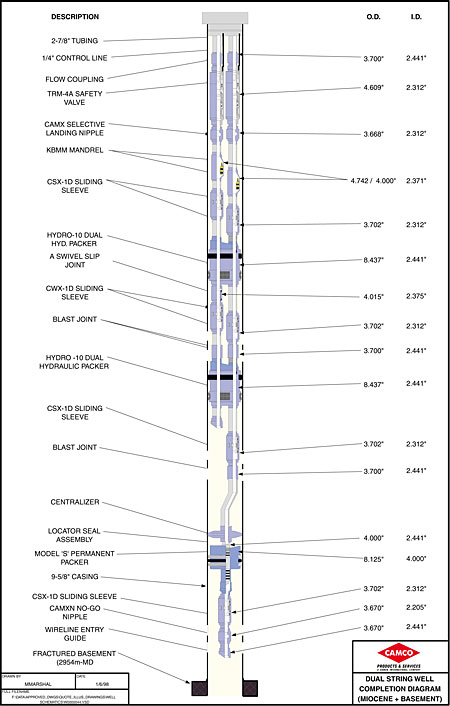

Gas lift is the controlled injection of gas into the oil as it enters the production tubing. As it does in nature, the gas lightens and propels the liquid to the surface allowing oil in the reservoir to move to the well and then to the surface. The key to gas lift is "control" and much has been done to design systems that inject the gas, either intermittently or continuously, at a rate sufficiently constrained to prevent gas waste yet also in volumes large enough to optimize oil production. Over time, systems have been devised to regulate the timing of gas injection, the volume injected, and, through the use of gas lift mandrels and valves situated along the tubing string, at what depth those volumes are injected into the fluid column.

But these systems are far from efficient. It is no industry secret that some gas-lifted wells are producing at a fraction of their capability and that much gas is being wasted as it flows from injection point to production line without actually affecting oil production.

Today, with the proliferation of computer technology and telemetric monitoring of well behavior, as well as the perfection of multiphase metering and pumping, gas lift efficiencies are poised to greatly improve. The goal is to maximize the "gas lift cycle" by setting the timing and volumes of gas injected into the well so as to optimally affect oil production while minimizing gas usage.

"The trick is setting the timing," said Herb Meyer of Camco, a leading industry supplier of gas lift systems. "The cycle could be four or five times a minute or one every few minutes. That is where the man in the pickup earns his money, by letting it cycle on a certain time and checking production, then changing it and checking production to see if it increased and on and on until it is optimum."

No longer satisfied with the limited kind of tweaking possible from even the most experienced field hand, Camco and others are currently at work to bring the process into the computer age, not only because of inherent human inexactitude, but because even when a cycle is set, changing well conditions quickly render it inefficient. The problem is particularly challenging to a manual solution when numerous wells are draining a single reservoir and adjustments to the gas lift settings on one well inevitably affect the others to create a cause-and-effect network too complex and often too subtle to be calculated by hand.

The solution to the complex problem of setting an optimum gas lift cycle is coming not so much from research on gas lift but as a beneficiary of development of other technologies, particularly on the heels of recent strides made in the difficult science of measuring multiphase flow. At present, measuring exactly what is flowing from any given well, that is the actual fluid makeup in percentages of gas, oil, and water, could only be determined through a production test. And since this requires manually turning flow to a separator, operators are loath to do it on anything but an intermittent basis, commonly once-a-week or less.

The solution to the complex problem of setting an optimum gas lift cycle is coming not so much from research on gas lift but as a beneficiary of development of other technologies, particularly on the heels of recent strides made in the difficult science of measuring multiphase flow. At present, measuring exactly what is flowing from any given well, that is the actual fluid makeup in percentages of gas, oil, and water, could only be determined through a production test. And since this requires manually turning flow to a separator, operators are loath to do it on anything but an intermittent basis, commonly once-a-week or less.

Naturally, with such a long time between tests and the fact that such a test shows only a moment in time that may not be very representative of the well's longer term flow makeup, it is impossible to "tweak" gas injection on any kind of timely or reliable basis.

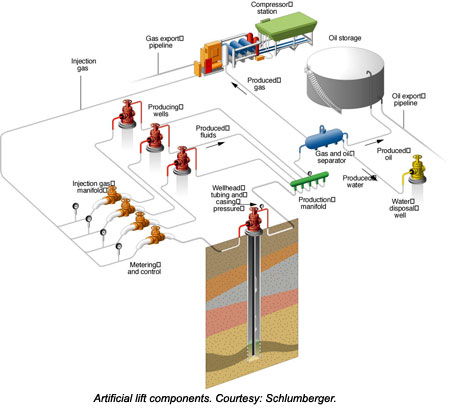

But with the introduction of multiphase flow metering in real time and SCADA telemetry, gas lift efficiencies can be monitored continuously and without production interruptions. The addition of computers that can read and analyze the data instantly and then make the necessary changes that consider optimizing the field as a whole promises to bring heretofore unseen efficiencies to what has always been considered an inexact science.

One key to the multiphase meter's role in gas lift optimization is its ability to measure the flow makeup with extreme frequency. In the case of a meter developed by Schlumberger and Framo, a reading is taken every 22 milliseconds.

"The high frequency measure gets rid of the effects of any type flow," said Schlumberger's Jeremy Walker. "Other ways to do that involve very large pieces of equipment. Gas lift causes instability and taking high frequency measurements you can measure the effects of changes you make (to the gas lift cycle) in real time."

Using multiphase flow metering, reported Walker, one large multi-well field was able to maximize its fluid production and minimize gas injection within five days.

Likewise, when a field is facilities-constrained, that is when the wells are capable of producing more than the field processing and gathering system can handle, the multiphase meter can be invaluable in optimizing production by assuring available facilities are used to accommodate the most productive wells in terms of revenue rather than waste gas on less productive ones. Without multiphase meter data, the guess work involved in such a decision can be wildly inaccurate because it is not merely a question of fluid volume wells are delivering, but at what cost in terms of gas injected and how efficiently that gas is being used.

Since the meter is sufficiently compact to allow each well to be equipped with one, an entire field can be tied together. When reservoir models and production data are added to the mix, the loop can be closed and injection as well as production rates set with an eye toward long field life, accelerated production or some combination in thereof.

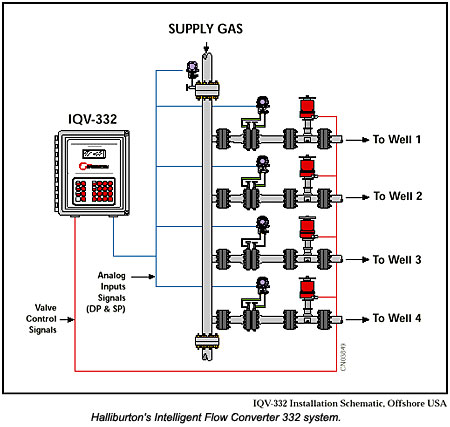

Another problems long vexing secondary recovery experts trying to set the gas lift cycle to optimum is presumption of constant gas supply. While it has long been understood that all gas supplies fluctuate causing gas to be wasted or production reduced, operators have long been resigned to the problem as nearly impossible to correct. But oil service giant Halliburton now claims to have developed an answer to gas supply interruptions through what it calls the Intelligent Flow Controller (IQV-332 for short).

According to company literature, the electronics-based system monitors gas supply variables and controls the injection choke to maintain a constant injection rate and can be applied to as many as four wells at a time. It works through six user-defined injection set points per well. The set points are based on each well's production curves and are stored in the IQV's memory. In the event of lift gas shortage, the IQV automatically supplies gas to the most productive wells first.

Using a somewhat different approach to improving efficiencies, Weatherford has chosen to create hybrid lift systems that combine gas lift with some of their mechanical secondary recovery tools such as progressive cavity pumps, electric submersible pumps, reciprocating pumps, and plungers.

Essentially all these systems seek to reduce the cost and therefore the size of the lift equipment on the surface while at the same time improving the efficacy of both the gas and mechanical lift systems. In each instance, gas is injected above the pump (or plunger) in order to reduce the fluid head and allow the mechanical component to more easily lift the fluid to the surface.

The company claims this method can reduce the liquid head, essentially the downward force resisting the ESPs and PCPs, by up to 40%. As might be expected, the systems are particularly useful in heavy crude situations that cause great strain on pumps and are often of too high a viscosity for gas to effectively lighten or propel.

Weatherford also advocates use of gas lift with the plunger, one of the older artificial lift systems that works by converting well gas trapped beneath it into pressure that carries it and a load of fluid above it to the surface. Essentially a piston-shaped mandrel whose outside diameter is near that of the tubing wall's inside diameter the plunger system has long suffered from a phenomenon known as "fall back". "Fall back" occurs when fluid clings to the walls of the tubing when being gas lifted and as the name would imply, falls back to the bottom of the well. Production loss from "fall back", particularly in deep or heavy-oil wells, can be considerably and the hybrid system can therefore significantly increase production and extend well economic life.

Gas lift is no newcomer to the oil industry. But in its long history its effectiveness has been defined by human limitations. By combining the older lift technology with new ones like data acquisition including accurate realtime flow measurements, simulation, and automation, as well as old ones like downhole pumps, greater efficiency and stability are now possible. As a consequence, the technology appears ready to live up to a whole new potential.

To review previous Technology Features on gas lift, click one of the tabs below:

http://www.oilandgasonline.com/doc/showlegacy/0AA30F0D-F42A-11D3-8C25-009027DE0829

http://www.oilandgasonline.com/doc/showlegacy/596044DD-F514-11D2-A405-00C04F4F7C39

http://www.oilandgasonline.com/doc/showlegacy/5DDAA5FE-4241-11D4-8C50-009027DE0829

To express your views on the subject of this article, go to our Discussion Forum by clicking here.