Measuring Multiphase Flow

Houston, Texas

Contents

Oil wells rarely produce a single type of fluid. Formation fluids are always a mix of liquid and gas with liquids further divided between water and hydrocarbons. This multiphase emulsion is by turns a hindrance and a boon to reservoir engineers seeking to describe, identify, and predict the behavior of producing zones.

In the first instance, the chaotically mixed flow of fluids makes it impossible, without first identifying the part played by each phase of the mix, to determine exactly what volume of hydrocarbon is being produced.

On the other hand, once a practical method is found to describe the makeup of the flowing fluids, its recipe can serve as a benchmark. From then on, changes in the fluid's makeup, combined with geological and engineering knowledge about the producing formation, can tell scientists a great deal about how the well should best be handled.

Watering Out (back to top)

Changes in produced fluids' percentage of water content, for instance, can signal engineers that the well is in danger of "watering out", that is, of producing water at the expense of oil. Armed with such knowledge, operators can often change production strategies in time to increase the percentage of hydrocarbon ultimately recovered from the reservoir.

Until recently, the sole method for measuring these complex, or multiphase, flows was to first separate them into their essential components of gas, hydrocarbon liquid and water. While a reasonably accurate procedure in most instances, it has drawbacks.

Separator units used to deconstruct the mixture, particularly offshore and in other areas where wells flow with high pressure, high temperature, high volumes, or any combination thereof, are quite large and heavy. They also usually must be run for extended periods, from several hours to many days, in order to provide reliable data.

Because of their bulk, separators raise significant space, logistics, and capital expense challenges for offshore platform designers. And separation test times often translate to significant revenue losses, even when hydrocarbons are recovered downstream of the well test.

Offshore, the separator itself is often housed on a host platform, frequently miles from the well to be tested. Such distances between wellhead and separator can change fluid stream characteristics and make accurate reservoir descriptions, particularly in exploration situations, problematic. As a rule, the closer measurement taking stations are to the reservoir face, the more reliable and less susceptible to error from interpretation is the data.

As these drawbacks to traditional testing methods become more urgent with increasingly deeper water, companies recently have begun to seek ways to replace them with flow measuring devices that are at once smaller and do not require separation.

While inventors vying for the market use different technologies to obtain an ultimate well flow rate, they all begin with a single flow stream density. "The first thing we do is measure density of the mixture going past," said Roxar's Bob Kettle. "That indicates to you how much gas is there because, of course, gas is very light compared to fluids."

Gas Fractions (back to top)

Once these percentages, or "gas fractions" are determined, companies use different approaches to describe the makeup, by percentage of oil and water, of the liquid phase. Kettle's Houston-based company uses microwaves.

"The frequency at which the microwave resonates gives you a very precise measurement of the dielectric constant and from that you get a good indication of how much [of the fluid] is hydrocarbon and how much is water because their individual dielectric constants are very different," Kettle said. "Using those two measurements, you are able to split the flow into three component percentages."

By that point, without separation, and more importantly, without having intruded into the flowline, a cross-section of the flow stream has been described within small margins of error.

Once components of the fluid have been established, most multiphase meters use a venturi meter for rate information. Essentially, it is a tube with a reduced diameter at one point. When fluid is flowed through it from larger diameter to smaller, pressure measurements are taken on either side of the size change. The pressure differential, when plugged into equations corrected for the specific meter and well, indicates mass flow.

But the method has a flaw, particularly offshore where the venturi is part of the subsea completion to be used for periodic well tests. With flow passing rapidly by the inner walls of the funnel-like venturi, erosion is almost inevitable. With any change in diameter, mass-flow calculations, will obviously render inaccurate answers. Debris or produced solids can plug or obstruct the small ports used to measure pressure differential, again affecting data reliability. And when the meter is submerged it is not easily inspected leaving these erosion effects undetected for some time.

The obvious answer to erosion, a function of abrasion from flow, is to eliminate the change in diameter at the measurement point. Just as obviously another measurement, independent of pressure change that will also lead to a flow rate is also needed. One answer is to very accurately measure flow velocity and combine that with knowledge already gained about the fluid's percentage makeup.

To do so, Roxar places two microwave devices along the flow line within a few inches of each other. Each measurement, essentially an infinitely small cross-section of the stream, is a unique pattern. By measuring the time taken for one pattern to travel the few inches, a very accurate velocity measurement is obtained and correlated with the composition measurements to derive well flow values.

"They are taking the measurements at about 1,000 per second," Kettle said. "You need to be going that fast because the chaotic mixture going past can change over a short distance. The computer must be very powerful."

Microwave Systems (back to top)

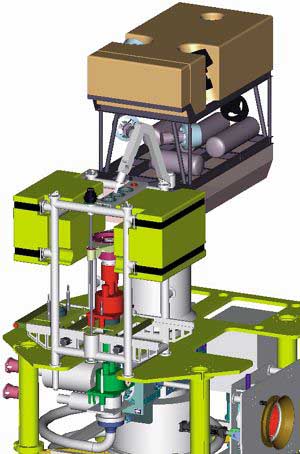

About 100 of the microwave-type systems have been installed around the world. Offshore, most have been installed in the North Sea and West Africa. They are built into flanged sections of pipe only a few ft long in 2-8-in diameters. They hold particular attraction for offshore applications as they can be easily fitted to subsea trees and, according to Kettle, are designed to last the life of the field.

So far, the Gulf of Mexico oil industry, renowned for its conservative ways in matters technological, has ignored multiphase meters. But that may change as the devices prove themselves in the North Sea and elsewhere and American engineers come to believe in their time- and cost-saving potential.

For instance, says Kettle in the most common subsea scenario with multiple remote wells connected from the seafloor to a single host platform, each well must have a dedicated test loop between well and separator. Or, barring that investment, a number of conjoined wells can be tested at once with each well shut in for a period of time to determine its contribution to the total production test.

With a multiphase meter on each well the inaccuracies of such practices are eliminated. "If you have a meter on each well, you can do allocations easier and more accurately," explained Kettle. "[That has] implications for the field, the well and the buyer."

Production well tests done with multiphase meters can be done in a fraction of the time required by traditional production test separators. "With a meter on the wellhead you can do [a production test] in 10-15 minutes, just taking a look at what the well is making," Kettle said."

Kettle expects industry interest in multiphase metering to begin to rise in the next few quarters as prices stabilize and operators again open their development drilling and completion budgets. In the deep waters of the Gulf of Mexico, West Africa and elsewhere, where space and time savings are critical, the size and convenience of multiphase meters may be just what operators are seeking.